When selecting engineered wood flooring, one of the most critical decisions involves choosing the right finish. The finish impacts not just the appearance and texture of the floor, but also its durability and the care it requires. Among the most popular finishes are oil-based, water-based, and UV-cured coatings.

Each type presents distinct advantages and disadvantages, rendering them appropriate for various settings and applications. We provide a comprehensive comparison of these three types of finishes to help you decide which is best for your flooring needs.

Table of Contents

ToggleOil-Based Finishes

Composition and Application Process:

Oil-based finishes for engineered wood flooring are typically composed of natural oils such as linseed, tung, or a blend of various oils and resins. The application process involves cleaning and preparing the wood surface, followed by evenly applying the oil finish with a brush, roller, or cloth. It might be necessary to apply many coats, allowing sufficient drying time between each coat before applying the next.

Oil-based treatments have a warm, rich, and natural appearance because they pierce deeply into the wood, emphasizing its grain. This adds visual appeal and aesthetic impact. The finish brings out the unique characteristics of the wood, giving it a more authentic and less glossy look compared to other types of finishes.

Advantages of Oil-Based Finishes

- Enhanced Natural Look and Feel: Oil-based treatments draw attention to the wood’s inherent beauty by showcasing its texture and grain. The result is a more organic and warm aesthetic that is often preferred for its authentic appearance.

- Ease of Spot Repairs and Maintenance: Small scratches and blemishes can be easily repaired by reapplying the oil finish to the affected area without needing to refinish the entire floor. This makes maintenance and spot repairs more convenient and less time-consuming.

Disadvantages of Oil-Based Finishes

- Greater Drying Time: Oil-based finishes require more time to dry between coats than other finishes do. This can extend the overall time required to complete the finishing process, making it less ideal for projects needing a quick turnaround.

- Potential for Higher Maintenance Needs: Oil-based finishes require more frequent maintenance to keep the wood looking its best. Re-oiling the wood on a regular basis is required to preserve the finish and shield it from deterioration.

- Susceptibility to Stains and Scratches: Oil-based finishes are generally less durable than polyurethane or other synthetic finishes, making the wood more prone to staining and scratching. This susceptibility requires more diligent care to maintain the floor’s appearance.

Water-Based Finishes

Composition and Application Process:

Water-based finishes are typically composed of water as the primary solvent, along with acrylic or polyurethane resins. The application process involves cleaning and prepping the wood surface, followed by applying the water-based finish with a brush, roller, or sprayer. These finishes generally require multiple coats, with each coat drying quickly before the next application.

Clear Finish and Minimal Yellowing: Water-based finishes offer a clear and non-yellowing coat, preserving the natural color of the wood. This characteristic is particularly beneficial for light-colored woods, ensuring they maintain their original appearance without developing a yellow tint over time.

Advantages of Water-Based Finishes

- Faster Drying Time: Water-based finishes dry significantly faster than oil-based finishes, allowing for quicker project completion. Its short drying time allows for the application of many coats in less time.

- Reduced VOC Emissions and Eco-Friendliness: These finishes are safer for indoor air quality and produce fewer volatile organic compounds (VOCs) than oil-based finishes. Their low odor and reduced toxicity make them a healthier choice for both applicators and occupants.

Disadvantages of Water-Based Finishes

- May Not Highlight Wood Grain as Effectively as Oil: While water-based finishes provide a clear and non-yellowing coat, they may not enhance the wood grain as richly as oil-based finishes. This can result in a less pronounced and less warm appearance of the wood.

- Requires Multiple Coats for Durability: To achieve the desired level of protection and durability, water-based finishes often require multiple coats. This can increase the amount of product used and the overall effort required to achieve a long-lasting finish.

UV-Cured Finishes

Composition and Curing Process:

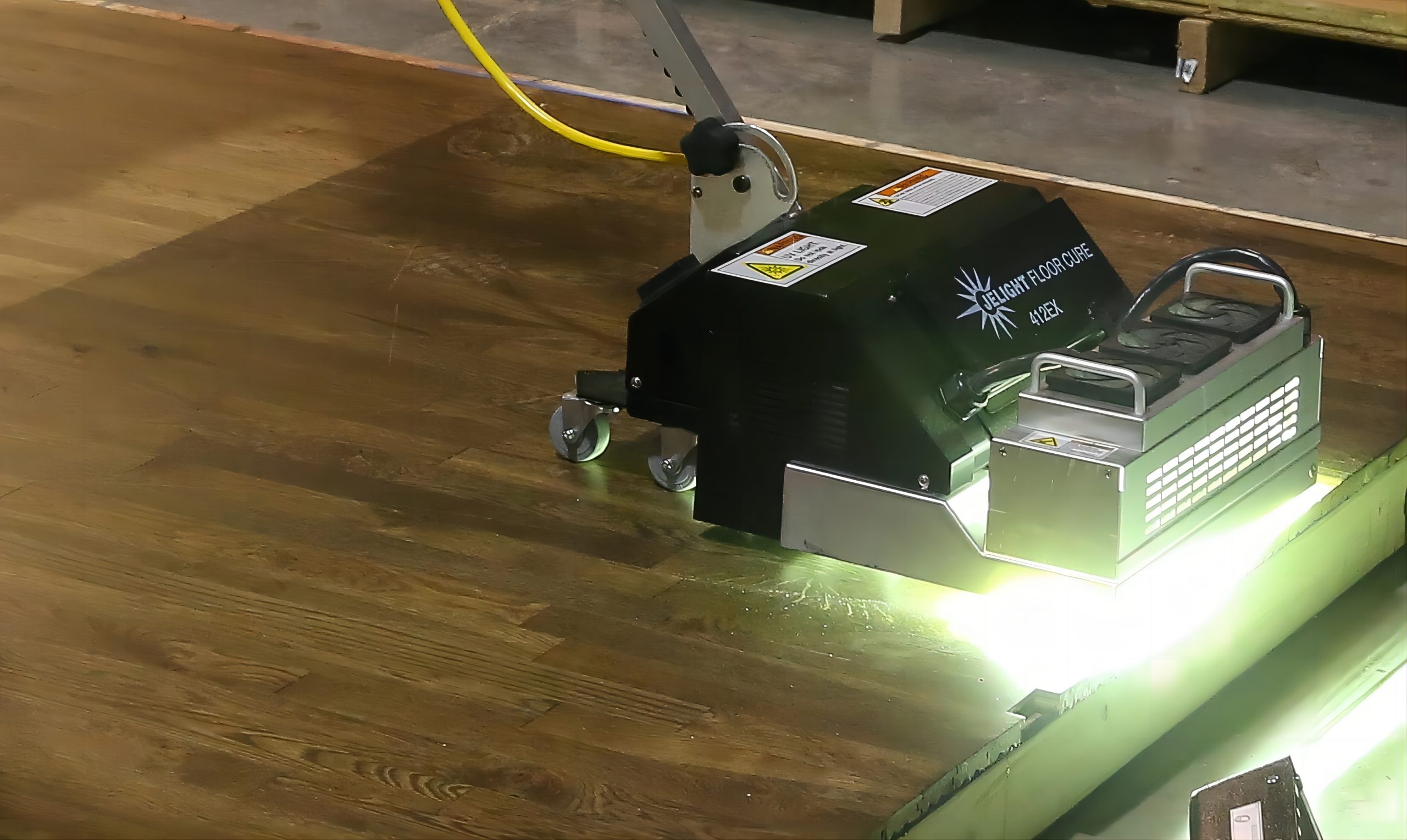

UV-cured finishes are made from a combination of acrylate monomers and oligomers, which polymerize under ultraviolet (UV) light exposure. The application process involves spreading the finish onto the wood surface, followed by exposure to UV light, which rapidly cures the finish, hardening it almost instantly.

High Resistance and Durability: UV-cured coatings are renowned for their remarkable resistance and durability. They create a hard, protective layer that offers superior resistance to scratches, wear, and various chemicals, making them ideal for high-traffic areas.

Advantages of UV-Cured Finishes

- Immediate Use Post-Installation Due to Rapid Curing: One of the most significant advantages of UV-cured finishes is the rapid curing process. Floors finished with UV-cured coatings can be used immediately after installation, minimizing downtime and inconvenience.

- Superior Resistance to Wear and Chemicals: The hardened layer formed by UV-cured finishes provides outstanding protection against everyday wear and tear, as well as chemical spills. They are therefore an enduring and robust alternative for engineered wood flooring.

Disadvantages of UV-Cured Finishes

- Specialized Application Process Requiring UV Light: The application of UV-cured finishes requires specialized equipment, including UV light sources, to properly cure the finish. This can make installation more difficult and require hiring an expert.

- Potential Higher Cost Compared to Traditional Finishes: Due to the specialized equipment and advanced technology involved, UV-cured finishes can be more expensive than traditional oil- or water-based finishes. The increased expense might be taken into account for initiatives with tight budgets.

Choosing the Right Finish

The decision to choose between oil-based, water-based, and UV-cured finishes largely hinges on your particular needs and preferences. If you value a natural look and are willing to invest time in maintenance, an oil-based finish might be the best choice. For those who prioritize durability and environmental factors, water-based finishes offer a compelling option. Meanwhile, UV-cured finishes are perfect for areas that demand the highest level of durability and the least maintenance.

When selecting a finish for your engineered wood flooring, take into account both the practical and aesthetic effects of each kind. Choosing the right finish for your flooring will not only improve its aesthetic appeal but also ensure that it remains useful and appealing for a considerable amount of time. As an engineered wood flooring manufacturer, selecting the right finish is crucial to ensure customer satisfaction and the long-term durability of your product.