A great approach to improve your home’s aesthetics, worth, and usability is to install engineered hardwood floors. Effective budgeting, however, requires an awareness of the associated expenditures. The kind of wood species, installation technique, laying pattern, labor costs, material waste, and other variables can all have a significant impact on the price of installing 1,000 square feet of engineered hardwood flooring.

Table of Contents

ToggleOverview of Engineered Hardwood Flooring Costs

The total cost of installing engineered hardwood floors is influenced by several key factors:

- Material Costs: The price of engineered hardwood planks varies by wood species, quality, and finish.

- Labor Costs: Charges for professional installation depend on the region, expertise, and complexity of the job.

- Installation Method: Glue-down, nail-down, floating, or click-lock methods affect the cost.

- Laying Pattern: Patterns such as straight, herringbone, or chevron require different levels of skill and time.

- Wastage: Typically, 5–15% of material is added for cutting and fitting, depending on the complexity of the layout.

- Additional Expenses: Subfloor preparation, underlayment, trims, and finishing add to the overall cost.

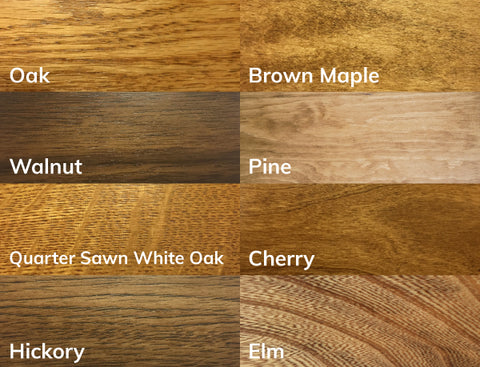

Material Costs by Wood Species

The cost of engineered hardwood planks varies depending on the species of wood:

| Wood Species | Cost per Square Foot (Materials) |

| Oak | $4–$10 |

| Maple | $5–$12 |

| Hickory | $6–$14 |

| Walnut | $8–$16 |

| Exotic Species | $10–$20 |

For 1,000 square feet, material costs can range from $4,000 to $20,000, depending on the chosen species.

Installation Methods and Costs

Different installation techniques necessitate different amounts of time and expertise, which affects labor costs:

| Installation Method | Cost per Square Foot (Labor) | Details |

| Floating | $2–$5 | Easiest and fastest method; planks snap together. |

| Glue-down | $3–$8 | Requires adhesive; suitable for concrete subfloors. |

| Nail-down | $4–$9 | Traditional method; requires nails and skill. |

| Click-lock | $2.50–$6 | Similar to floating; locks securely without adhesives. |

For 1,000 square feet, labor costs can range from $2,000 to $9,000 depending on the installation method.

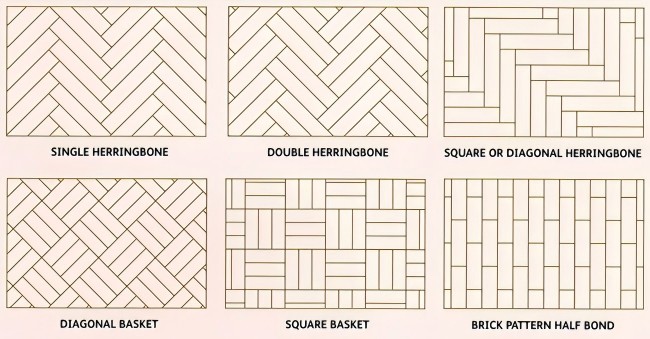

Costs Based on Laying Patterns

Complex patterns increase both material wastage and labor costs:

| Laying Pattern | Labor Cost per Square Foot | Wastage Percentage | Notes |

| Straight/Plank | $2–$5 | 5–10% | Standard and most cost-effective pattern. |

| Diagonal | $3–$7 | 10–15% | Requires precise cutting and alignment. |

| Herringbone | $4–$10 | 15–20% | Intricate pattern; increases labor time. |

| Chevron | $5–$12 | 15–25% | More complex than herringbone. |

Choosing a herringbone or chevron pattern can add $1,000 to $2,000 to labor costs and require extra materials.

Subfloor Preparation Costs

Subfloor preparation is essential for a durable installation. The subfloor’s condition affects the costs:

| Subfloor Condition | Cost per Square Foot | Details |

| Minimal Preparation | $0.50–$1 | Simple cleaning or leveling. |

| Moderate Preparation | $1–$3 | Small repairs or sanding needed. |

| Extensive Preparation | $3–$6 | Major repairs or full leveling. |

For 1,000 square feet, subfloor preparation can cost between $500 and $6,000.

Additional Costs

Other expenses to consider include:

| Item | Cost | Details |

| Underlayment | $0.50–$2 per square foot | Enhances soundproofing and stability. |

| Baseboards and Trims | $2–$5 per linear foot | Provides a finished look. |

| Moisture Barrier | $0.50–$1 per square foot | Essential for installations on concrete. |

| Disposal of Old Floor | $0.50–$2 per square foot | Removing and hauling away old flooring. |

Estimated Total Costs for 1,000 Square Feet

Below is a breakdown of the estimated total costs for different scenarios:

| Cost Component | Low Estimate | High Estimate |

| Materials | $4,000 | $20,000 |

| Labor | $2,000 | $9,000 |

| Subfloor Preparation | $500 | $6,000 |

| Laying Pattern (Wastage) | $200 | $2,000 |

| Additional Costs | $1,000 | $4,000 |

| Total | $7,700 | $41,000 |

Budgeting and Cost Management Advice

- Compare Quotes: To get the greatest deal, get several quotations from contractors.

- Choose Simple Patterns: Opt for straight or plank patterns to reduce labor and waste costs.

- DIY Where Possible: Consider DIY installation for floating or click-lock floors.

- Plan for Wastage: Purchase 5–15% more material to account for cutting and fitting.

- Invest in Quality: By reducing maintenance costs over time, professional installation and premium materials can result in financial savings.

Conclusion

The price of installing 1,000 square feet of engineered hardwood flooring varies greatly based on a number of variables, including labor, supplies, installation technique, and more. You should budget between $7,700 and $41,000 on average. Understanding these expenses and making appropriate plans will help you create a stunning, long-lasting floor that suits your spending limit.